In today’s rapidly evolving industrial landscape, material handling robots have emerged as a game-changer. These sophisticated machines are designed to automate the process of moving, sorting, and organizing materials within manufacturing facilities or warehouses. With their ability to streamline operations and enhance efficiency, material handling robots have become an indispensable asset for businesses seeking to optimize their supply chain management.

The Role of Material Handling Robots

Material handling robots play a crucial role in various industries by taking over repetitive and physically demanding tasks that were traditionally performed by human workers. These robots can lift heavy loads with precision and accuracy, reducing the risk of injuries associated with manual labor. Moreover, they can operate continuously without fatigue or breaks, ensuring uninterrupted workflow.

By utilizing advanced sensors and artificial intelligence algorithms, material handling robots can navigate complex environments autonomously. They are capable of identifying obstacles in real-time and adjusting their path accordingly to avoid collisions. This not only enhances safety but also minimizes downtime caused by accidents or damage to goods.

Youibot: Revolutionizing Material Handling Robotics

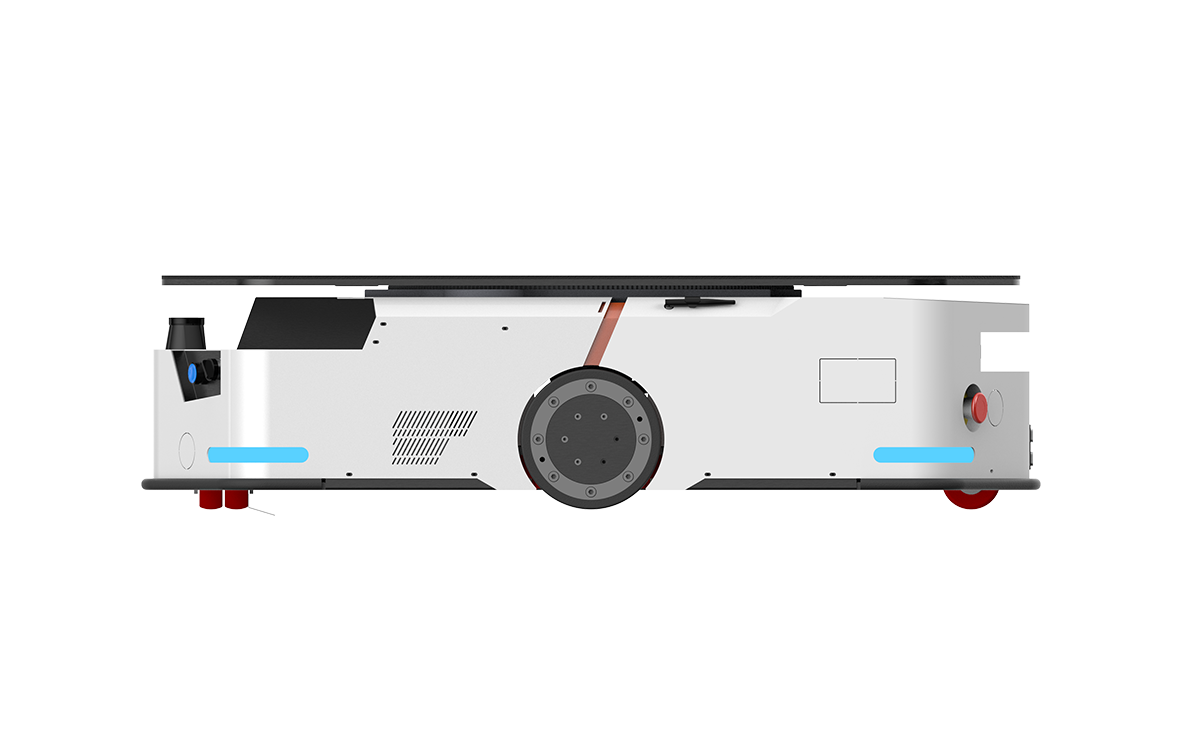

One notable player in the field of material handling robotics is Youibot – a leading provider of intelligent mobile robot solutions. Their state-of-the-art robotic systems combine cutting-edge technology with user-friendly interfaces, striking the perfect balance between features and simplicity.

Youibot’s robots are equipped with advanced perception capabilities that enable them to perceive their surroundings accurately. Through simultaneous localization and mapping (SLAM) algorithms, these robots create detailed maps of their environment while localizing themselves within it. This allows them to efficiently navigate through dynamic spaces without requiring any external infrastructure modifications.

Additionally, Youibot offers intuitive software interfaces that allow users to easily program tasks for the robot using drag-and-drop functionalities or predefined templates. This user-friendly approach eliminates the need for extensive programming knowledge, making it accessible to a wider range of users.

The Future of Handling Robots

As technology continues to advance, material handling robots are expected to become even more versatile and intelligent. The integration of machine learning algorithms will enable these robots to adapt and learn from their experiences, further enhancing their efficiency and decision-making capabilities.

Furthermore, advancements in collaborative robotics will allow material handling robots to work alongside human workers seamlessly. By incorporating safety features such as force sensors and collision avoidance systems, these robots can operate safely in close proximity with humans, opening up new possibilities for efficient collaboration between man and machine.

In Conclusion

Material handling robots have revolutionized the way businesses handle logistics operations by improving productivity, reducing costs, and ensuring workplace safety. With companies like Youibot pushing the boundaries of innovation in this field, we can expect an exciting future where material handling processes are fully automated and optimized for maximum efficiency.